Precision Pendulum

A precision pendulum is easy to construct once we get the right materials. The "World Pendulum" was design in a very robust way but a simplified version with common materials is described here.

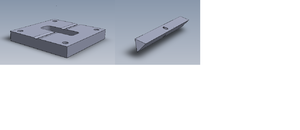

The basic support can be a wall or a robust metallic structure like the one presented here. The choice for the mass was a training steel weight from the official shot put with 2kg. This weight has the advantage of having a drilled hole for holding a M4 screw and can be find in any good sports shop. This screw can be made of a threaded brass rod with 10mm length. A small 1mm hole is drilled on the rod were the pendulum string is soldered using current soldering thin (or a silver alloy). The string used is from 0.4mm remanium wire that can be bought in any dentistry retailer. The other end is soldered to the same brass rod with a length of 50mm, using the same technique (1mm hole and soldering).

The support is made from any robust plane surface made from a brass or stainless steel piece with a 12-16mm hole. This surface have a scratch made with a diamond or hard steel blade were the pivot work. With this design slippering is avoid.

String measurement

The pendulum precision