Difference between revisions of "Precision Pendulum"

| Line 10: | Line 10: | ||

==String measurement== | ==String measurement== | ||

| − | The pendulum accuracy depends strongly in it's length | + | The pendulum accuracy depends strongly in it's rigorous length measurement (2,7 m). Indeed this is the crucial factor to achieve the desired 0,1% accuracy and for that propose a well calibrated measuring tape as to be chose. Alternative methods like ultrasonic measurement with laser targeting are the best, using a metallic or marble stone plane fitted tangential to the weight (allowing it to roll but touching the plane). With this method a few takes shall be done surrounding the ball and their average value will be considered the pendulum reference length. |

Recalibration of the length as to be pursuit every month to guarantee a reasonable precision. | Recalibration of the length as to be pursuit every month to guarantee a reasonable precision. | ||

Revision as of 12:41, 22 November 2012

An accurate pendulum is easy to construct once we get the right materials. The World Pendulum was design in a very robust way but a simplified version with common materials is described here.

The basic support can be a wall or a robust metallic structure like the one presented here. The choice for the mass was a training steel weight from the official shot put with 2kg. This weight has the advantage of having a drilled hole for holding a M4 screw and can be find in any good sports shop. This screw can be made of a threaded brass rod with 10mm length. A small 1mm hole is drilled on the rod were the pendulum string is soldered using current soldering thin-plumb(or any silver-thin alloy). The string used is from 0.4mm remanium wire that can be bought in any dentistry retailer. The other end is soldered to the same brass rod with a length of 50mm, using the same technique (1mm hole and soldering).

The support for the fulcrum is made from any robust plane surface made from a brass or stainless steel piece with a 12-16mm hole. This surface have a scratch made with a diamond or hard steel blade were the pivot work. With this design slippering is avoid.

String measurement

The pendulum accuracy depends strongly in it's rigorous length measurement (2,7 m). Indeed this is the crucial factor to achieve the desired 0,1% accuracy and for that propose a well calibrated measuring tape as to be chose. Alternative methods like ultrasonic measurement with laser targeting are the best, using a metallic or marble stone plane fitted tangential to the weight (allowing it to roll but touching the plane). With this method a few takes shall be done surrounding the ball and their average value will be considered the pendulum reference length.

Recalibration of the length as to be pursuit every month to guarantee a reasonable precision.

Gate system

To avoid a long run of the experiment to achieve a reasonable period accuracy readout with a normal chronometer one could use instead a gated photodetector connected to an acquisition system or to a precision pulse counter.

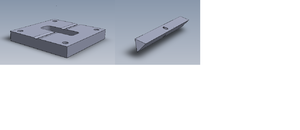

The World Pendulum design can be easily adapted as it consists on a photodiode mounted in a aluminium holder (20x20x6 mm3)with a central 1,5mmhole and a 4mm vavity on the back side(see design).

In front of the photodiode a solid-state laser beam from a normal pointer device is used to trigger the counter once the ball hide the light.