Difference between revisions of "Precision Pendulum Assembly: Mechanical assembly"

| Line 42: | Line 42: | ||

[[Precision Pendulum Assembly: Electrical interfaces| Next Page: (Electrical interfaces)]] | [[Precision Pendulum Assembly: Electrical interfaces| Next Page: (Electrical interfaces)]] | ||

| + | |||

| + | ==Links== | ||

| + | |||

| + | *[[Montagem do pêndulo de precisão: montagem mecânica | Portuguese Version (Versão em português)]] | ||

| + | *[[Conjunto de péndulo de precisión: ensamble mecanico | Spanish Version (Versión en español)]] | ||

Revision as of 01:15, 4 April 2021

Contents

Mechanical assembly

In this section is describe the procedure to assemble the tripod metallic structure also known as Primary Pendulums.

Order of assembly and filling with sand

- Screw the three plastic base support under the triangular base and level the base with the help of a spirit level;

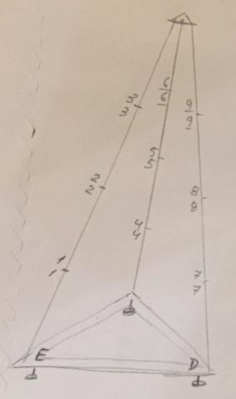

- Fit together the three lower sections of each leg following the numeration presented in the figure below;

- Fix each one of the legs to the triangular base by tightening the provided screw and taking into account the letters "E" and "D", as shown in the figure below leaving the screws a bit loosy;

- Fill the legs with sand while the whole structure is standing in the vertical (use a table or step ladder);

- Fit the last section of each leg following the numeration;

- Fit the aluminum top plate and tighten it slightly to each one of the legs using the screws;

- To check that both top plate and base triangle are aligned, one can lean the whole structure against a wall and adjust the top plate in accordance if necessary. Once both aligned, firmly tighten the screws of the (i) bottom triangle followed by the (ii) top plate;

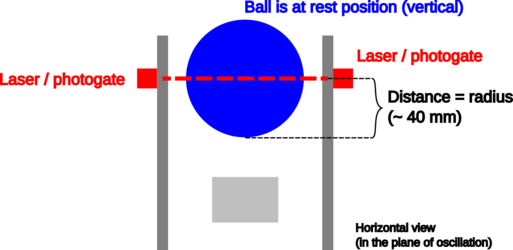

- Pass the bob cable and fix it in such position that the equatorial plane crosses the photo-gate, as shown in the schematic below (Horizontal view);

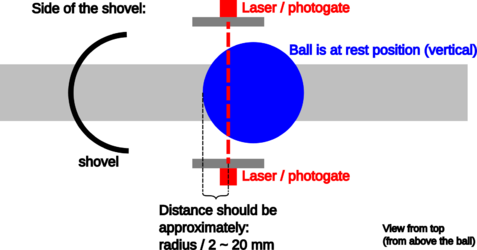

- Align the whole structure (regulating the height of the three pads touching the floor) so that the horizontal rest position of the ball relatively to the laser beam is as specified in the schematic below (View from top);

- Having the bob at rest, start the pendular movement by slowly excite the fulcrum in the top;

- With the help of a flashlight in the front of the shovel and putting a white paper on the shovel other end adjust the horizontal tilt screws in order to have the launcher platform aligned with the plane of oscillation. This can be seen easily if the shadow center of the bob do not move horizontally.

|

|

|

|

|

|

Wall mount assembly

The simplified version of the pendulum is delivered as a toolkit to be fixed in a masonry or concrete wall. It do not include the tripod and consists on the launcher with shovel and the top holder to sustain the fulcrum.

The main aspects to retain on the fixture is (i) to have all structure completely tied-up and firmly secured, (ii) the launcher perfectly horizontal and (iii) aligned with the natural plane of oscillations (please refer to previous sub-section "Order of assembly").

Maintenance

The main components of the launcher should not need any maintenance; do not lubricate any part except the rail in case it gets sticky. For that end it should be disassembled, clean with a soft tissue and alcohol and lubricated lightly with a very small amount of grease on the linear bearing or vaseline. Check if every rolling sphere is working properly.

If the shovel's cable (over the rail) broke it has to be substituted by a steel cable with a track capability of 250 N, typically found as fish lines of 25m coils. If the location is in a hard climate were corrosion show-up it can be replaced by an equivalent dynema cable.

Please let it have two turns on the motor's shaft. Although the string position is not critical we have found that in some situations is preferable to have it between the shovel and the motor. Nevertheless never use a high tension on the cable as it can jeopardize the fast movement of the shovel. Usually 2-5 N should be enough to avoid slipping in the shaft.

Next Page: (Electrical interfaces)